Introduction

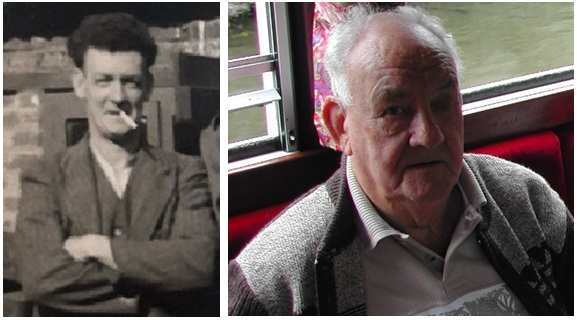

My Father (Dad) Joseph Lishman Hogg was born in Felling Gateshead-On-Tyne in the North East of England in 1918 to my Grandfather Edward Hogg and Grandmother Polly Lishman. After School in 1934 my Dad followed his Father being an Apprentice Non-Ferrous Sand Moulder at Clark Chapman’s Co Ltd who made components for Battle Ships built on the river Tyne and elsewhere in England and Scotland.

Royal Navy Battleship Prince Of Wales

My Dad’s main memory was that he made most of the Non-Ferrous, Brass and Bronze wheel components for the Royal Navy Battleship HMS Prince Of Wales which was launched in 1939. In 1941 during the second world war HMS Prince Of Wales along with HMS Repulse were sunk by a Japanese Navy Submarine in the South China Sea whilst protecting the Malay Peninsular known as the ‘Battle of Malaya’. This made my Dad very Sad as he as part of the Ship Building Workforce were not allowed to join the Military and all of his work went to the bottom of the sea with some of the brave Royal Navy personnel.

What is Sand Moulding ?

During the Industrial Revolution of the early from the1900’s to 1950’s Sand Moulding was the prime construction technique for making Ferrous (Iron) and Non-Ferrous (Other Non Iron) Metal components. Its basic principle is that you make a Mould of a Pattern Component using Sand in a Metal or Wooden Box and then remove the Pattern and replace the empty space with Molten Metal which takes up the shape of the Pattern known as a ‘Casting’. This is done by using a Bottom and Top Sand Mould. However, it was very important to ensure the sand was not wet as I will illustrate later.

Dad used to make far more complex component Moulds than these which required very skillful fine adjustments to the Moulds to ensure accuracy. He used specialised tools for Tools doing this work. I have seen my Dad work and its like a work of art creating the sand shapes.

The Foundry

A Foundry big and small is the place where the Moulds and Castings are made. They are usually very dusty, hot and very dangerous places to work. In a small Non-Ferrous Foundry it contains the ‘Furnace’ which heats the Metal, Brass, Copper and Aluminum contained in a ‘Crucible’ to a molten state ready for pouring into the Mould. This is done normally by two men with a special cradle holding the Crucible. Foundries also have Grinding and Polishing machines for final finishing of the Castings.

Dad did all of these actions which was very heavy and dangerous work. He also used to re-line the Furnaces with new Fire Bricks to ensure effective heating.

Non-Ferrous Metal Knowledge

My Dad had a thorough knowledge of all different types of Brass, Bronze, Aluminum and Aluminum Alloy and other Metals used for different Components. These Metals were normally stored as Ingots which were then placed in the Crucibles with some Chemicals to reduce air bubbles at times for melting in the Furnace. Sometimes scrap metals could be melted given that the content was known for example Brass as shown below.

Foundry Management

My Dad was a very Skillful and Knowledgeable Foundry Craftsman so much so he was sought after by many Foundries in England as a Manager. His first was the Partner and Manager of a small Foundry in Ludham Village Norfolk . He then moved to a Foundry in Norwich Norfolk as a Manager. Much later we moved to Keighley in West Yorkshire where he Managed a much larger Foundry.

Major Accident

Whilst he was the Manger at the Foundry in Keighley Dad received a major injury caused by some Molten Metal hitting his left Eye and his Trilby he was wearing which saved his right Eye. This was caused by two Moulder’s who did not check the Sand which was too wet. When the Molten Metal was poured into the Mould it exploded causing the Molten Metal to spray out. My Dad was very unlucky as he happened to be walking by when the explosion took place. After being taken to hospital in Bradford a town nearby and further examination my Dads left Eye was removed. Miraculously his right Eye was untouched.

Return to Ludham Foundry

After recovering from his accident he decided to return to Ludham Foundry which needed him Manage the small Foundry again due to flagging sales. This was his last position and he retired living with my Mum in Ludham until she passed away. He then lived in a Nursing Home close to my Sister in Caister-On-Sea until he passed away when he was 95 years old.

A Great Craftsman and Dad

My Dad was a great Craftsman and Foundry Manager and most of all a great Person, Husband, Father and Grandfather which we miss very much. It is important for us to remember my Dad and his profession which he enjoyed so much. Finally, I am very lucky to have 2 Cat Face Ashtrays Moulded and Cast in Brass and Polished by my Dad many years ago which I treasure very much.